Manufacturing Analytics

Transform your business with a data-driven approach to industry 4.0 and faster, fact-based decisions. Qlik helps manufacturing organizations use data to optimize processes, improve supply chain agility, and better serve the modern customer.

Explore Manufacturing Analytics

Digitalization creates a step-change opportunity for operational improvement and innovation

Industry 4.0 and IoT deliver the machine and product performance that manufacturers need to improve operations. Qlik ensures faster time-to-value and streamlined processes by surfacing highly accurate and groundbreaking insights across the entire product lifecycle.

Improve production throughput

Analyze Overall Equipment Efficiency (OEE) easily to understand uptime at each production site and improve throughput. Qlik’s associative technology brings together all key machine-level data, such as availability, performance, and quality, so manufacturers can determine which factors are improving or worsening and which have the greatest operational impact.

-

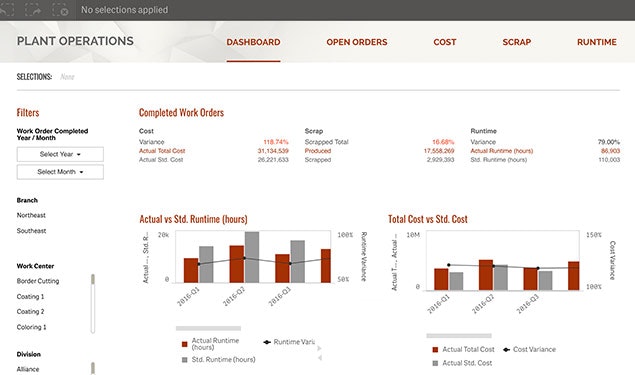

Better understand plant operations

Visualize actuals versus standards for all your critical KPIs. Qlik analyzes every data source, from production yields and scrap percentages per completed order, to machine runtime and work order volume. -

Leverage IoT data to continuously innovate

BMW Group uses Qlik to harness their machine-generated data. Whether that data comes from paint-spraying robots on the factory floor or diagnostic outputs from cars being serviced, BMW Group now has the insights they need to develop future “customer-valuable processes.” -

Make sense of complex manufacturing data

Discover how Qlik can leverage manufacturing data to identify root causes, spot sales opportunities, and innovate products and services ahead of the competition. -

Understand quality issues in context

Learn how Terex uses Qlik to analyze quality data and perform root cause analysis to reach a ‘zero defects’ product stance.

Explore top manufacturing analytics resources

Supply Chain Visibility (SCV) is core to managing complex enterprise ecosystems

Manufacturers must overcome supply chain complexity to ensure multi-channel, demand-driven inventory availability and pursue after-market opportunities. This requires harnessing data from disparate data sources both internal and external to the company. Qlik can connect directly to ERP, SCM, Forecasting, MES, and other internal systems, as well as external data sources like third-party logistics and consumer demand/sentiment — with no data warehouse required — to guide decision-making and surface potential supply chain issues.

-

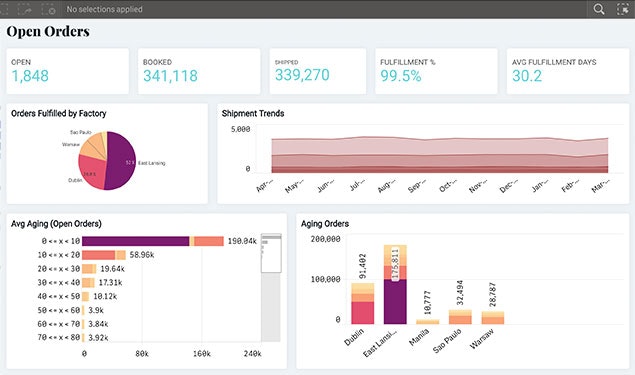

Take control of your supply chain to better serve customers

The Qlik Associative Engine makes exploring any data source across your supply chain easy, be it internal or external, big data or small. Instantly search and analyze every aspect of your supply chain to gain better insights to make your organization far more responsive to dynamic customer trends. -

Streamline Sales & Operations Planning (S&OP)

The S&OP process integrates financial targets, tracks Point of Sale actuals over time, monitors open orders, and builds forecasts. Our data indexing technology is uniquely adept at combining data that pulls from systems (e.g. Finance, Operations, Sales) to simplify and accelerate the S&OP process. -

Meeting the challenges of many markets

Extracting SAP data with Qlik Data Integration then analyzing with Qlik Sense enables us to tell the whole story through data and that is a huge benefit. -

Transform disparate data into a profitable growth driver

Qlik has helped thousands of companies gain visibility into — and control of — their supply chain with smarter analytics. By improving insight across the entire ecosystem, supply chain leaders are able to strike the optimal balance between availability, quality, and cost to drive profitable growth.

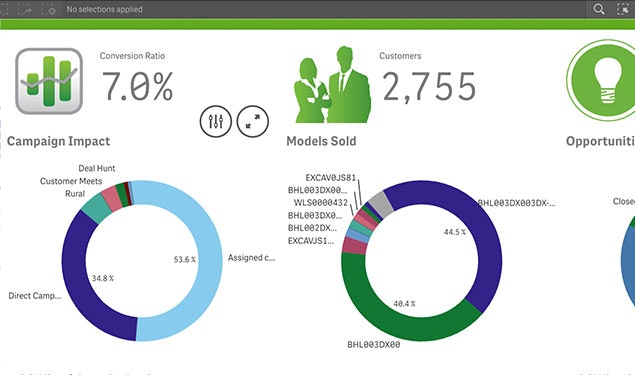

When it comes to modern innovation, consistent customer engagement is the key

Today’s customer has access to information to instantly compare almost any competing goods or services. Manufacturing companies that can understand customer sentiment and preferences — responding in line with rapidly shifting demand — will be the ones that drive innovation, capture market share, and deepen customer loyalty.

-

Sense and respond to shifts in demand in real-time

By leveraging point-of-sale data via self-service analytics, WD-40 uses Qlik to improve real-time demand-sensing accuracy and increase visibility into customer trends and proactively respond to competitive pressures. -

Understand automotive dealer performance

Search and explore across all your data in any direction with no pre-aggregated data or predefined queries to hold you back. Quickly probe for insight with interactive selections and global search, and instantly pivot your thinking based on what you see. Take away the limits from your analytics. -

Provide the evidence to drive cross-functional improvements

Using Qlik, Sony has deepened its knowledge of customer behavior and product performance across channels. The insights gained have helped Sony improve areas of the business such as marketing, commercial, customer insight, management, finance, and its own retail stores. -

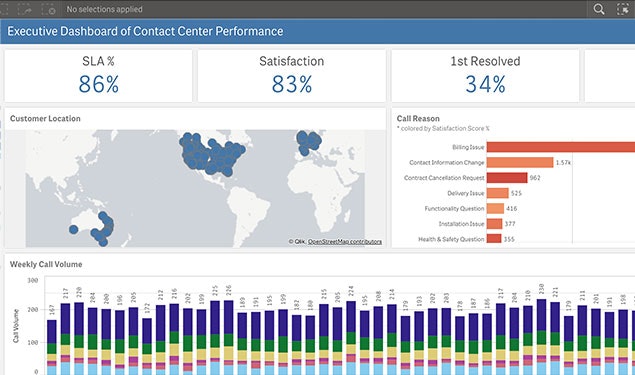

Measure customer service and call center effectiveness

Qlik can provide comprehensive visibility into customer service operations in a single analytics app. Easily track top-line performance. Quikly drill into operational details like service issue trends, channel dynamics and ticket resolution. And measure how well specific locations and agents can resolve issues in a timely manner.